At Talon/LPE, we have an obligation to be stewards of the land and its natural resources. These resources are precious, and limited. We protect our clients by offering safe and cost-effective solutions to their environmental concerns. We feel that we are meeting the obligation to be stewards of the land when our clients consider us valuable team members.

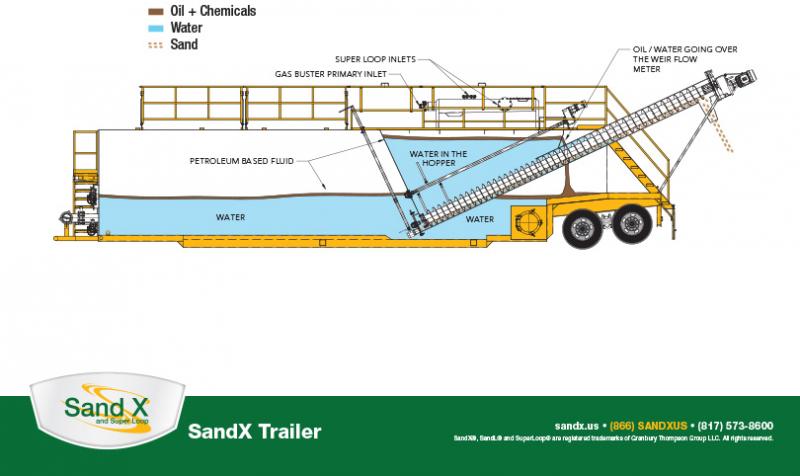

We strive to bring our clients the most innovative, efficient and cost-effective technology in the industry. That’s why we’re teaming up with Sand X. Our primary goal is to help you succeed, and with Sand X, it’s possible.